新闻资讯

倍耐力稻壳白炭黑

2021年02月02日 16:12

http://annual-sustainability-report-2013.pirelli.it/en/environmental-dimension/research-and-development-raw-materials/silica-rice-husks#.YBjt_DOBqrA

倍耐力

稻壳白炭黑

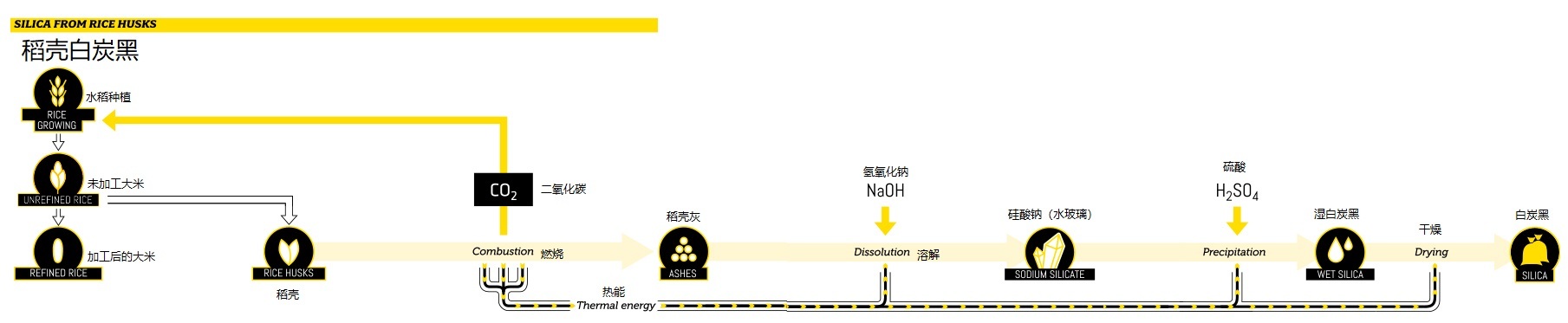

二氧化硅用于轮胎中,以降低滚动阻力,提高车辆效率,而不会降低其路面保持力,尤其是在潮湿条件下。在对越来越多的可持续材料的研究中,倍耐力一直在通过寻找传统加工方法的替代来源来专注于这种原材料。

该集团已在其位于巴西南部著名的大米生产中心Santa Catarina州的工厂开发了一种工艺,该工艺可从稻壳中提取二氧化硅。稻壳是稻谷的外壳。稻壳占生米重量的20%,是稻米加工的主要废料。鉴于全球大米产量,世界许多地区都有大量稻壳。稻壳已经具有许多或多或少复杂的应用:从牲畜垫料到有机肥料,再到用于发电的固体燃料。实际上,稻壳具有很高的能量含量,达14 MJ / kg。但是,它在世界上欠发达的地区尚未得到认可,并且在田野中燃烧而未开发其潜力。

除了其有趣的能量含量水平外,稻壳还具有另一种可利用的特性,其高二氧化硅含量占其重量的18%。在传统方法中,二氧化硅是通过化学方法制得的,其中结晶的二氧化硅(通常是沙子)溶解在水和苛性钠(NaOH)的溶液中。该过程中第一步的结果是硅酸钠。然后加入酸(通常为硫酸)以获得二氧化硅沉淀为主要产物,硫酸钠为副产物。结晶二氧化硅与苛性钠的反应需要大量的热能。但是,当稻壳燃烧时,产生的灰分是由非晶硅组成的,其最大残留碳含量为8%。与结晶二氧化硅相比,这种二氧化硅在初始反应中所需的能量要少得多。不难想象,这种生物质因此可以构成生产二氧化硅沉淀物的理想原料。如果以正确的方式燃烧稻壳,就可以产生生产所需的全部热能,同时,非晶态二氧化硅的反应温度要比传统方法低得多。

由于生产过程是热自给自足的,因此从稻壳生产二氧化硅不仅可以回收能量,而且还可以显着减少CO2排放,这恰恰是因为所有必需的热能都来自可再生生物质的燃烧。该处理活动已包括在与意大利环境部合作开展的研究项目中。

有关此项目的更多信息,请参见本报告“社会层面”一章中的“与机构和公共行政部门的关系”部分。初步分析表明,此过程在碳足迹方面具有巨大优势。与传统加工技术制成的二氧化硅相比,用稻壳制成的倍耐力二氧化硅可以减少90%以上的碳足迹。

倍耐力用稻壳生产二氧化硅是一个明显的例子,充分说明了材料领域的创新是如何完全可持续的,这有助于副产品的开发,否则副产品只能部分再利用,并且生产过程的生态可持续性也很高。所有这些好处都伴随着可以直接与过程效率相关的经济优势。

2013年初,世界上最负盛名的报纸之一《经济学人》也对该项目进行了报道。在倍耐力的一篇文章中,该期刊提到了使用可再生资源所产生的物质所带来的环境效益。倍耐力设定了自己的目标,即到2017年将稻壳获得的二氧化硅的使用范围扩大到高级轮胎。

下一条

相关新闻